Aflatoxin - Public Health Threat

Aflatoxin is a dangerous fungal carcinogen from toxigenic Aspergillus mold species which naturally inhabit soil around the world and favor high heat and humidity. Contamination in maize, peanuts and cassava – staple food crops across Sub Saharan Africa (SSA) - is a serious food safety and public health risk. There is no cheap and easy way for small-scale farm households in SSA to remove maize kernels contaminated with aflatoxin.

Aflatoxin has been linked to up to 35% of childhood stunting (a critical malnutrition indicator) in SSA.[i] Aflatoxin exposure in mothers during pregnancy has shown a strong effect on growth of the infant in the first year of life.[ii] Studies have also linked stunting with dietary exposure to aflatoxins upon weaning.[iii] Because malnourished children have a higher risk of death from common childhood illness (diarrhea, pneumonia, and malaria), nutrition-related factors contribute to about 45% of deaths of children under 5 in SSA each year – i.e., 1.26 M of the total 2.79 M child deaths.[iv], [v] Dietary aflatoxin exposure in SSA may be linked to up to 4.5 M new cases of childhood stunting each year, 440,000 deaths of children under 5 (15.75% of total child mortality).

Mini Aflatoxin Sorter

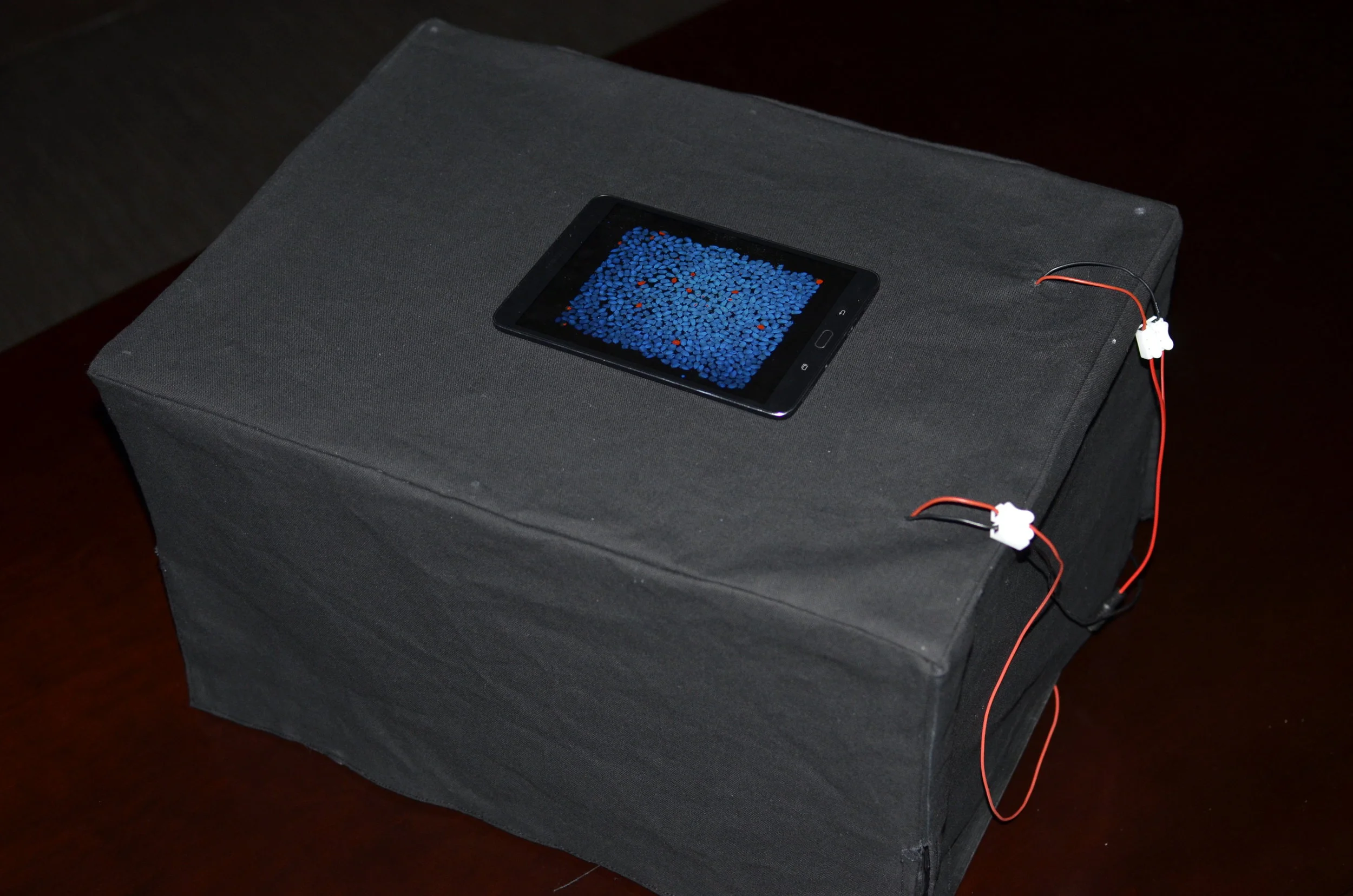

The Mini Aflatoxin (MAF) Sorter is the only rapid, low-cost, easy to use method for farm families in SSA to screen household lots of maize and remove aflatoxin contaminated kernels.

The MAF-Sorter consists of a lightweight, portable sorting box with Android tablet and camera, specialized UV lighting and filter, rechargeable battery, and software app with computer vision algorithm for rapid detection and manual sorting of maize contaminated with aflatoxin. The app also performs an augmented reality function that overlays red marks on the contaminated kernels for quick and easy detection and removal. As smartphone adoption and cellular coverage grow across SSA, developing an MAF-Sorter smartphone app has the potential to eliminate the tablet cost of the device, and increase device adoption and usage.

This patented technology is based on the unique spectral fluorescence of aflatoxin contaminated corn. Aflatoxin contamination in maize is not easily detected under normal light; but under high intensity, narrow bandwidth 365 nm UV light a contaminated kernel reflects a distinct bright green-yellow fluorescence (BGYF), different from the blue fluorescence of a healthy kernel. A tablet camera is faster and more effective at detecting BGYF kernels than the human eye, which has very low sensitivity at shorter wavelengths.

MAF-Sorter Performance

Trials with the prototype of the MAF-Sorter (2014-17), with US corn, showed reductions of 89-99% of the aflatoxin contamination in maize batches (with a rejection rate of less than 1.5% of total maize).

Quick & Comprehensive Screening

Since contaminated kernels are often not uniformly spread throughout a bag or field, comprehensive post-harvest screening of entire lots is necessary - and only possible with the MAF-Sorter - to find and remove potentially dangerous kernels prior to milling and consumption. The MAF-Sorter enables the user to sort approximately 12 kg/hour (0.2 kg batches of shelled maize; 60 seconds/batch). After drying and shelling, batch sorting can be done in a similar lot size as household milling in about 1 hour of added work per week.

Easy to Share

The MAF-Sorter is lightweight and portable, and sharable at the village level, among members of a village-based farming group, church, mosque, etc. (enabling co-ownership models that improve affordability and cost-effectiveness). It is not uncommon for women in a community to work together on the task of milling, so co-ownership and sharing of the MAF-Sorter may complement existing practices. Plus, device rental and fee-for-service models can provide additional income to device owners.

Low Cost

Through co-ownership of the device at the village level, the $200/unit cost of MAF-Sorter can be spread across 20 households, for an individual household cost of $10, for use of the device. Additionally, device rental and 3rd party fee-for-service models can also lower the cost of access to the device. The only other potentially available option for some farm households in SSA is the use of biological controls (like Aflasafe) to suppress toxigenic fungal infection – at a cost $12-20/hectare per season. For the treatment to be effective, it must be applied every crop season, for an annual cost of $24-40/hectare. Even with this application aflatoxin contamination can still occur during post-harvest storage, since poor storage practices remain a problem in most farm households in SSA.

Income Generation

Device rental and 3rd party fee-for-service models can provide additional income to device owners - $20 (USD) per week, or about $1,000 per year (20 households per week, 1 hour/household, $1/hour).

[i] Feed the Future. Agrilinks. Aflatoxin Infographics and Related Sources. https://www.agrilinks.org/post/aflatoxin-infographic-and-related-resources.

[ii] Paul Turner, et al. (June 2007). 'Aflatoxin exposure in utero causes growth faltering in Gambian infants.' International Journal of Epidemiology 2007; 36:1119 – 1125.

[iii] Yunyun Gong, et al. Determinants of aflatoxin exposure in young children from Benin and Togo, West Africa: the critical role of weaning.' International Journal of Epidemiology. 2003 Aug;32(4):556-62.

[iv] The World Bank. World Bank Open Data. https://data.worldbank.org/.

[v] World Health Organization. Children: reducing mortality. https://www.who.int/news-room/fact-sheets/detail/children-reducing-mortality.

Mini Aflatoxin Sorter (prototype) with canvas cover.

Ears of corn under high intensity, 365 nm UV light. Contaminated kernels reflect a bright green-yellow fluorescence, different from the blue fluorescence of healthy kernels.

Tray of kernels under high intensity UV light with MAF-Sorter tablet, using augmented reality feature to mark kernels in red that are suspected of aflatoxin infection.

MAF-Sorter tablet live feed of a tray of kernels under ordinary light with augmented reality feature marking suspicious kernels in red for easy detection and real-time manual sorting.